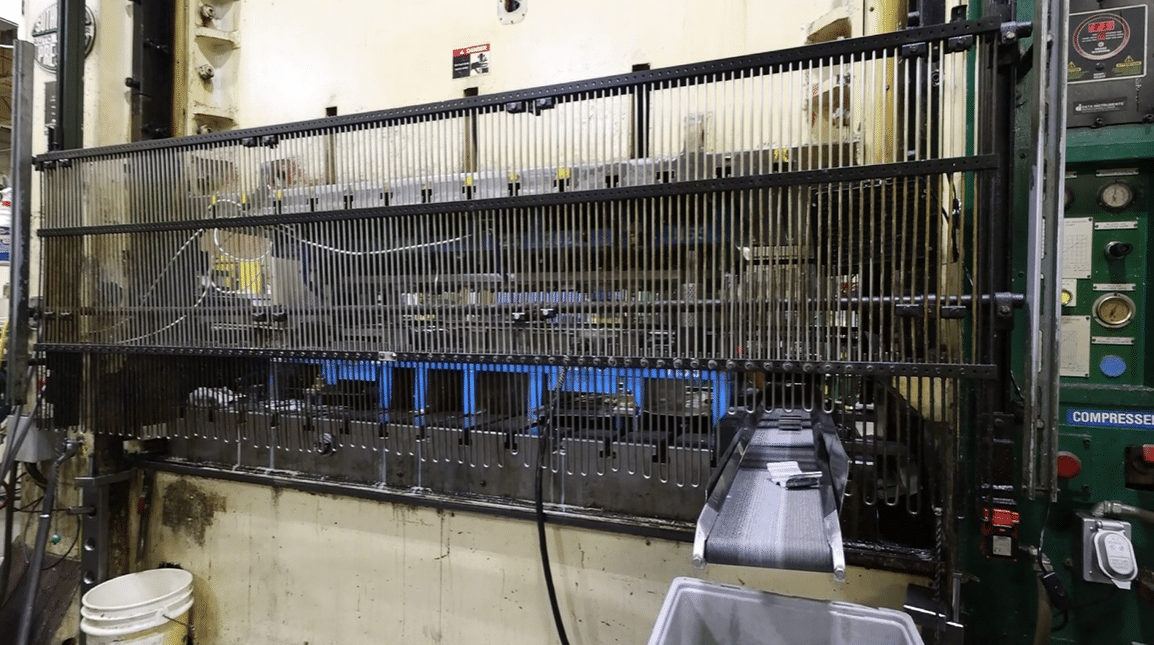

Atlantic Tool & Die Co. is a leading manufacturer that offers global engineering and metal stamping services. Our facility uses state-of-the-art equipment to provide precision metal stamping for our clients in various industries. We have the capabilities and capacity to achieve any of your custom metal stamps needs.

What is Precision Metal Stamping?

Metal stamping is a process where markings are punched into the metal material to create shapes or designs. They turn metal stamps in different shapes and cuts, which we can use for further fabrication.

Precision metal stamping requires precision tools and machines capable of producing complex designs accurately and quickly with little or no waste.

Other benefits of Precision Metal Stamping:

- Great for high-volume orders: Labor costs drop as production increases, making it an excellent choice for larger orders.

- Low die costs: Dies for metal stampings are cost-effective since they only cost a little to produce and maintain.

- Consistent quality: Precision metal stampings allow for incredible accuracies, such as the exact parts required in many industries today.

- High level of automation: Machines used in this method are easy to automate as we can use computer-controlled programs for faster production and quick turnaround.

These advantages make precision metal stamping an excellent option for various industries, such as automotive, aerospace, food and beverage, medical, and more. These industries often need accurate metal parts and components, which precision metal stamping can provide.

Main Applications for Precision Metal Stamping

As mentioned above, precision metal stamping is used in different industries for a variety of different applications.

Here are some examples of applications:

- Metal clips

- Brackets

- Friction plates

- Weights

- Frames

We can metal stamp light-gauge metal components to more prominent and thicker metal components and assemblies allowing us to create a variety of metal parts for our customers.

Different Forms of Precision Metal Stamping Techniques

We provide effective forms of precision metal stamping processes that can deliver optimal results. The techniques we use will depend on the outcome you want to receive.

Punching

Punching is a metal forming technique where punches and dies are cut through a metal sheet to produce the desired shape. It’s used when complex shapes are needed, such as slots, louvers, or embossed features.

Coining

Coining is when edges are struck to flatten or break the burr, creating a smoother edge in the coined area. It also adds additional strength to localized parts of the material.

Bending

Bending is when force is applied to change the shape of the material. We use it to bend the material to the desired angle or shape.

Embossing

Embossing is a technique where the metal’s surface is stamped with patterns to produce a raised effect. It’s reversely used as debossing for a recessed effect.

Flanging

Flanging is swiping the sheet metal or partially formed metal in a direction that produces a flange or lip. It’s used to attach components and make them more rigid.

Choose a Manufacturer with Quality Precision Metal Stamping Abilities

Atlantic Tool & Die is dedicated to providing a trustworthy manufacturing process with our precision metal stamping technique to deliver quality products to meet your needs. If you have any questions, make sure to contact us or request a quote.