If you’re looking for a top-notch tube manufacturing partner, look no further than Atlantic Tool & Die Co. We specialize in high-quality tube manufacturing – our cutting-edge technology and industry expertise have earned us an enviable reputation as one of the foremost providers of custom-made tubes on the market.

With our commitment to superior engineering methods backed by outstanding customer service, we get it right the first time to produce exact specifications that meet your demanding needs.

Overview of Tube Manufacturing

Tube manufacturing is a process used to create metal tubes and pipes of various sizes, shapes, and materials. The process begins with raw material in the form of a coil, which passes through a series of processes like cutting, punching, milling, swaging, forming, and welding until the desired shape and size are created.

Depending on the type of metal being used and the end-use application, the tube manufacturing process can involve several stages, including hot rolling, cold drawing, or extrusion. For example, stainless steel tubes may require thermal treatment such as annealing or pickling after fabrication.

The Tube Manufacturing Process

Tube manufacturing is a complex process that involves multiple steps, which include:

- Create a tube blank using either extrusion or drawing methods. After the tube blank is made, it needs to be bent into shape on a CNC tube bending machine.

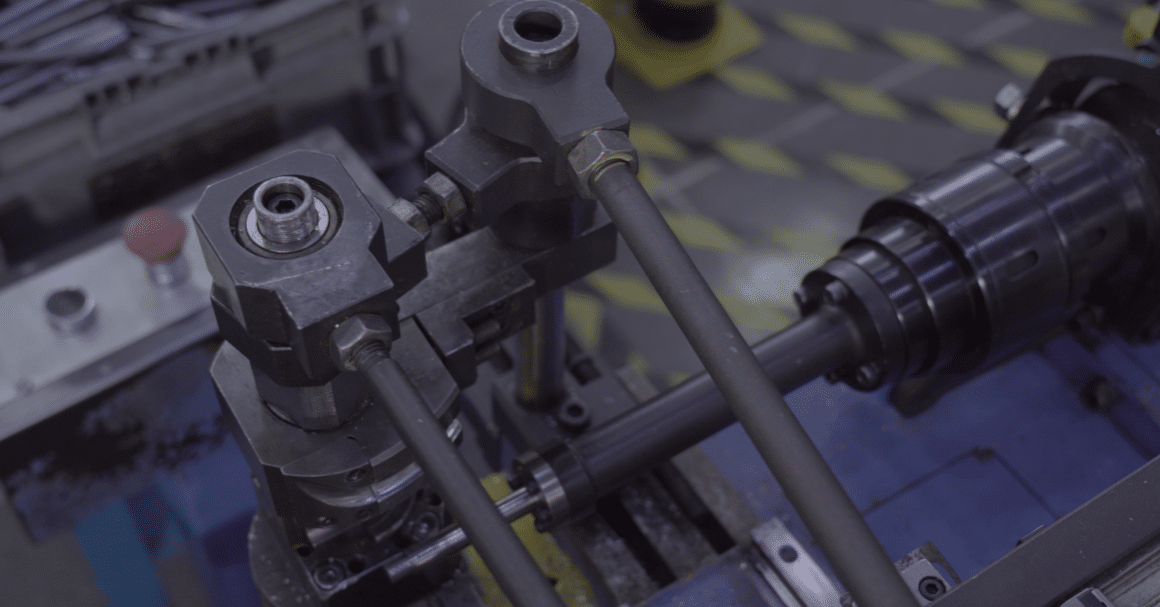

- CNC bending machines are programmed with exact parameters and use a hydraulic press, electric, or mechanical power to bend tubing into the desired shape. Depending on the part’s complexity, several bends may need to be created for the final product to match its specifications. The CNC bending machine can accurately control each angle and radius of each bend, resulting in consistent results every time.

- Once all of the bends have been made, any necessary welding processes may be performed to finish off the tube. This process can involve using a TIG welder, MIG welder, or even an orbital welder, depending on the material and application of the finished product.

- Finally, all tubes may need to be inspected and tested for quality assurance purposes before being shipped out. This could involve a variety of tests such as hydrostatic testing, radiography, ultrasonic testing, pneumatic testing, and more. Once the tubes have been approved for shipping, they’re ready to head out to their final destination!

Applications of Tube Manufacturing

Tube manufacturing is widely used in various industries, from automotive to the medical sector. Tubular products are essential for many everyday items, such as vacuum cleaners, bicycles, lawnmowers, and appliances. Tubes can also be used for structural applications such as building supports or guardrails.

In the automotive industry, tubular components are found in engines, transmissions, and exhaust systems. In the medical field, tubes can be used to create prosthetics or orthotic devices which help improve patients’ mobility.

Tubes are also used in furniture production, providing stability while remaining light. Additionally, they can be used to create piping systems for water supplies and air conditioning.

Tube Manufacturing at Atlantic Tool & Die Co

From the smallest of tubes to the largest, Atlantic Tool and Die provides a broad range of tube fabrication services. Whether it’s CNC bending, end forming, laser welding, or fabricating tasks such as hole piercing and notching, our team is ready to work with you.

Our specialized machines can bend, flare and expand tubes ranging from 6mm-63mm (1/2 – 2.5″). With full digital CO2 MIG/MAG welding capabilities and expertise in working with stainless steel, aluminum, copper, and steel materials, Atlantic Tool & Die enables high-quality custom tube manufacturing for diverse shapes, sizes, and complicated designs.

We offer on-time delivery with cost-effective solutions so our customers always get the best results. Contact us today to learn how Atlantic Tool and Die can meet your custom tube fabrication needs.